There's a problem that everyone who ferments food on a regular basis runs into. What's a good way to limit the aerobic activity at the top of the make? Also, if it's a solid application like a miso (AKA amino paste), how do you keep it compacted when the carbon dioxide starts to build? There are many solutions, but none of them present a practical and inexpensive way that can be customized to just about any vessel. We think we're onto something that fills the void.

Custom Fermentation Lid (Side View)

A lid that is just smaller than the opening of the vessel while in contact with an amino paste is how miso barrels/vats are designed. The lid is sturdy enough to support weights/stones above to maintain the compression during fermentation. This allows as much contact area as possible with a gap that allows carbon dioxide to escape and liquid to overflow above the lid. However, the readily available vessels folks reach for are mason jars and they're not designed for this. The common solution for fermenting food in jars is to add an air lock to the cover so oxygen cannot get in and the carbon dioxide build up eventually limits aerobic activity. However, it doesn't address maintaining the compaction of an amino paste during fermentation. We addressed this limitation with a neat work around, but it's not adaptable any other vessel that one would choose to ferment in.

Custom Fermentation Lid (Bottom View)

So what are the common solutions for covering and weighting the top of an amino paste aside from a fermentation barrel and matching lid? It's pretty much weights for mason jars and crocks that don't quite cover the entire surface and require supplementing, most commonly with plastic wrap. There's always the option of using a bag of salted water, which can match the shape of a vessel. However, it's fairly limited by the density, tend to be difficult to keep in place and aren't friendly when it comes to adding weight above. These solutions are just workarounds for the custom lid and they're not great.

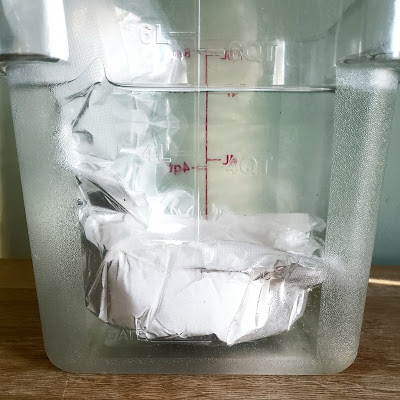

Compressed Table Salt is Denser than Water

Let's get back to the idea of being able to practically and inexpensively form a custom lid. The lids used in miso fermentation barrels are cut to size. What if you could use just three things to accomplish the same thing on practically any vessel with much less effort?

All you need is a vacuum sealer, a vac bag roll width that is at least a couple inches larger than your vessel opening and table salt. As we all know, a box of salt is fairly heavy for its size. The density of salt is 2.16 g/cm3, which is more than twice the density of water at 1.00 g/cm3. We chose table salt because it's fine and can be compressed to eliminate as much air as possible. A quick water displacement test of the vacuum packed salt lid weighing 3.25 pounds puts us pretty much in the middle at 1.5 g/cm3. We found out quickly in our initial experiment that kosher salt does not compact as well and you pretty much end up with the same density as water, so it floats. The reason why we want the cover to be more dense than water, so it will sink if you're using it for an application to hold the solids below the brine.

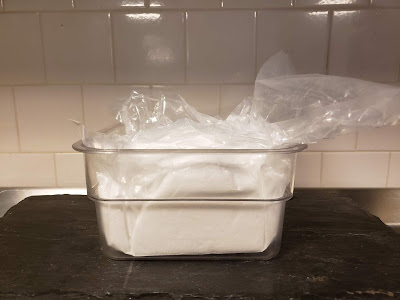

Custom Vacuum Packed Salt Lid Set Up

Yes, we have considered using water plus table salt to fill the gaps help improve the density, but it's messier and is difficult with a home vacuum sealer. We didn't go with a sand, metal shot or ceramic powder as we were looking for a low cost solution that is accepted as food grade even though it doesn't come in contact. Those who have dealt with strict food safety inspectors will understand. If these are not limitations to you, feel free to explore these further.

To make your lid, you first need to make the mold for the salt to fill. Measure three inches down from the top of the fermentation vessel and mark in a few locations with kitchen/masking tape. This assumes that you'll have two inches of salt and one inch of head space. Fill the vessel with any grains to the tape mark. Next, determine the length and width of the vacuum bag roll you'll need to cut. Position your vacuum sealer so the the opening is just above the vessel. The closer you get, the less bagging you'll need. Pull the bagging out until you are confident that you can fill salt on top of the grains that is 2" thick and be able to vacuum seal the bag. For really large vessels, you'll have make a two piece lid split at the middle. Cut and seal one side to make the bag. You know what to do from here. In some cases, you may need to use the handle of a wooden spoon to get the salt to fill in the edges. There you have it. Your custom lid that took longer to set up than make and the toughest part was finding the books to get the vacuum sealer to the right level.

As a side note, if you want to use this to weigh down ferments like kraut, kimchi, pickles or other applications you want to get solids below the brine. You just have to increase the gap between the cover and vessel opening. You can do this by cutting a long 2" wide strip of cardboard or whatever is flexible and gives you the gap you want and cutting it length so it can be placed in as a collar inside the vessel above the grains. This strip of material will make the salt lid smaller by the thickness.

As background, we've done a little homework on what's out there for larger weights. The only ones we know of are the split doughnut shaped weights made for lacto-fermentation crocks. There are ceramic and glass versions. For a direct comparison, the custom salt weight we made in the circular vessel here is the size you'd use an off the shelf one gallon split doughnut weight for. Let's do a quick and dirty calculation. The ceramic weight is $20 and weighs 2.5 pounds. That puts us at $8.00/pound. Assuming you have access to a home vacuum sealer, which is reasonable these days, here's the breakdown. The cost of a standard 26 oz container of table salt is just under $1. Two containers coincidentally put us at the size we needed, so that's $2. On top of that, let's say the bag costs $0.50. The salt is $2.50 of materials and weighs 3.25 pounds. That puts the salt solution at $0.77/pound and that's ten times less. Also, as we mentioned before, it's not ideal for keeping all the solids below the brine and not the answer for containing a miso.

In closing, we're here because we ferment a lot and want everyone to have the flexibility of using any fermentation vessel. As part of that, we want proper containment, because it's less work to ensure good results. We think this is a pretty great solution. Yes, there are issues that come along with using a vacuum bagged salt. Concern about the plastic being punctured, then it's game over. Keep in mind that this is not easy to do. Vacuum bags are made to take a beating. Think about all the rough handling of the insane amounts of vacuum packed products that are frozen, piled up and transported everyday. Of course, there are things you can do to ensure it won't break. Bagging it a second time is the first thing that comes to mind. Putting a plate/tougher insulator to take the beating if you want to add weight on top.

If you have access to a commercial vacuum sealer and want to do this with standard square restaurant style containers. Use the shorter containers of the same size opening as the mold to make the salt lid. Follow through the sequence of pictures below.

Short Square Container to Form the Salt Lid Shape

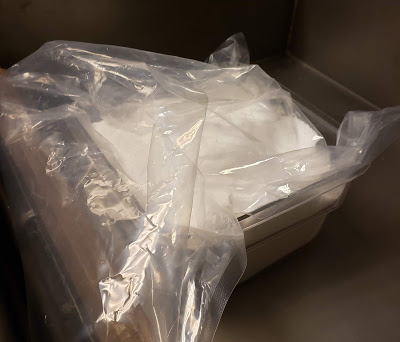

Vacuum Packing in the Container in the Chamber

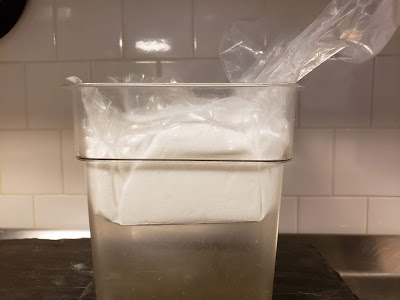

Vacuum Packed Salt Lid Fits the Deeper Container

We hope you're as excited about the potential of this idea as we are. We just came up with it and haven't had a chance to put it through its paces, so let us know your experiences. Do you have improvements and maybe even a better way?

As always, please share your discoveries so we an keep the ideas bouncing.